Lyndall Brakes Doubles Down on American Manufacturing and Industry-Leading Performance.

San Marcos, TX – July 1, 2025 — Lyndall Brakes, a leader in premium braking systems for

motorcycles, proudly reaffirms its unwavering commitment to manufacturing high-end wheel and

brake components entirely in the United States. From initial design and materials sourcing to

forging, machining, polishing, and finishing, every step of the Lyndall process is done on

American soil—and with unmatched precision.

“We take pride in doing things the right way,” said Paul Kittrell, CEO of Lyndall Brakes. “That

means using the best materials, working with the best craftsmen, and building every part here in

the U.S.A. from start to finish. No shortcuts, no compromises.”

This dedication to quality isn’t just talk—it’s backed by performance. Lyndall Brakes is the only

brake company in the world to offer a lifetime guarantee against warpage on its rotors. Thanks

to carefully selected materials, proprietary designs, and manufacturing processes, Lyndall rotors

are engineered to stay true for life.

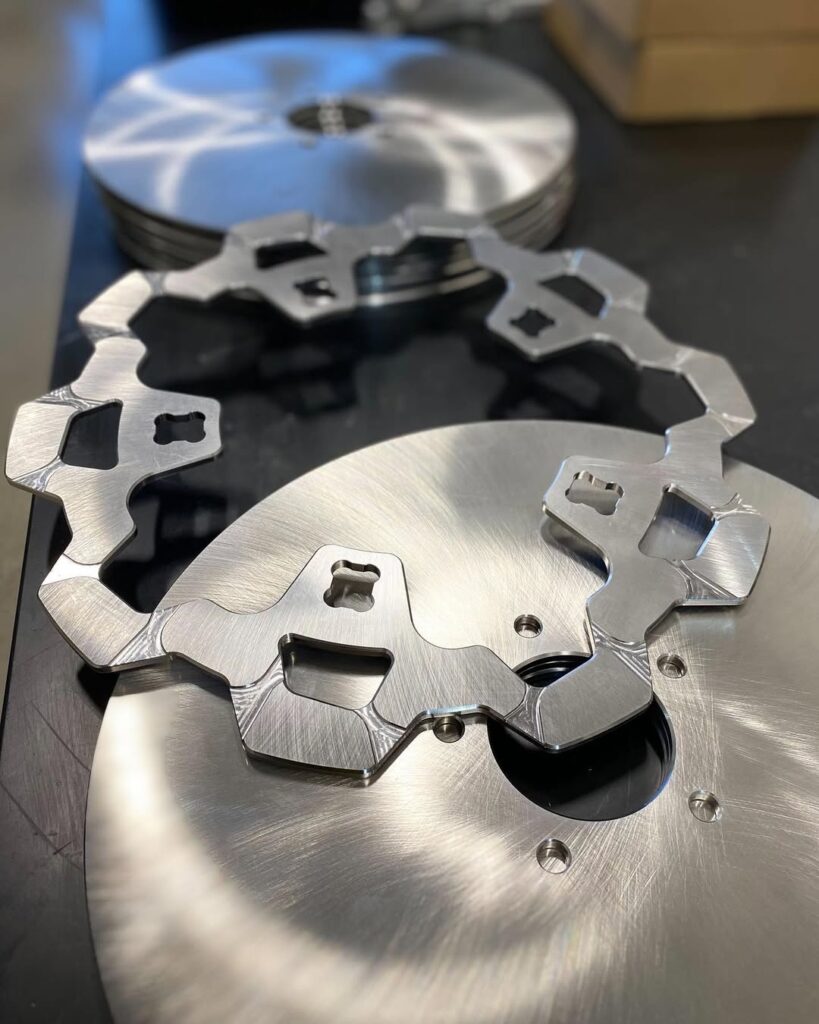

The company’s innovative “Bow-Tie Cut” rotors are a testament to its pursuit of performance.

Weighing just over 2 pounds per rotor, they are among the lightest steel rotors on the market

today. Reducing rotating mass on a motorcycle improves throttle response, acceleration,

handling, and braking performance—giving riders more control and a more responsive ride.

Lyndall Brakes has also unveiled the world’s first truly monolithic forged wheel—a

groundbreaking product forged and finished entirely in the USA. Engineered as a direct

plug-and-play solution for Harley-Davidson models, these wheels are a one-piece marvel of

strength, precision, and weight savings. Designed to enhance performance while simplifying

installation, Lyndall’s forged monolithic wheels represent a new pinnacle of American

motorcycle innovation.

“Our goal is to give riders an edge they can feel, whether they’re carving canyons or hitting the

track,” Kittrell added.

Lyndall Brakes continues to push the envelope with new product development, manufacturing

techniques, and performance enhancements—staying ahead of the curve while staying true to

American craftsmanship.

For more information, contact:

Lyndall Brakes

San Marcos, TX

(800) 400-9490

info@lyndallbrakes.com

More Stories

The RKB Tri-Fives Invader Wheel offered by Led Sled

CARDO SYSTEMS GOES BEYOND: INTRODUCING A NEW STANDARD IN MOTORCYCLE HELMET INNOVATION

Lyndall Brakes Begins Production on World’s First Truly Monolithic Wheel for V-Twin Motorcycles