There’s not much left of this project that “needs” done, but there’s always something else that “wants” done..

Sometimes that leads me to finding upgrades I didn’t know I wanted. The bike was running great. The weather was

warming up and between the flooding storms and the very rare tornado going past the house, and I managed to

get out and enjoy the bike. But I kept hearing something… at idle that didn’t seem… right. Like a soft knock, but not

a “this is gonna be expensive” knock.

After doing some research and talking to the smarter people, I came to the conclusion that it was either a worn

compensator, or inner primary bearing. At first, I thought it was no big deal, then I saw how deep into the primary I

had to go to get to the bearing and the dollar signs start adding up…If I’m gonna have it apart that much, I might as

well up grade this, but then I have to take apart that, so why not also change … cha-ching, cha-ching.

This next part may make some of the “elders” wince but I never really liked the look of the belt drive. The pulley

just looked… clunky. Its big, it hides the wheel and it just didn’t fit the bike as I thought it should. I thought a big

530 chain would be a cool look while adding more detail that is (much like me) just a little off from the

mainstream.

The chains from yester-year (century) were problematic, required a lot of maintenance and have ruined millions of

pairs of jeans. These “new” ones with the O-rings, X-rings, alloys and all the other upgrades made in the last 150

years, aren’t the same as the ones your dad or grandpa had. I was sold on the idea of going with a chain but finding

one that was available and reliable was a bit of struggle for a 6-Speed Twin Cam Softail. After some digging, and a

phone call, I ended up ordering a kit from Vulcan Engineering Company, www.vulcanworks.net.

I knew as soon as I called them, this was the type of company I wanted to do business with. A true small business,

everything made in house. When I called, a gruff sounding guy answered the phone. I stated I had some questions

about the Softail chain conversion kit they offered. “Yeah, hang on a min,” then he set the phone down. While

waiting, I could hear the unmistakable sound of CNC machines whirring, the pulsating sound of cutting tools

turning metal stock into chips at a high rate of speed, and the sound of guys on the shop floor muttering about this

and that. Finally a different guy answered the phone and he had all the answers. I asked about reliability, how it

works, why theirs worked, and why other companies said it was hard to get it right. The guy on the phone took the

time to explain everything to me. I sorted out what I wanted and got clarification on some chain options. It was

clear I was talking to a company that not only makes the parts, they use the parts, and their collars would be blue if

they weren’t stained with sweat and CNC coolant. My kind of place.

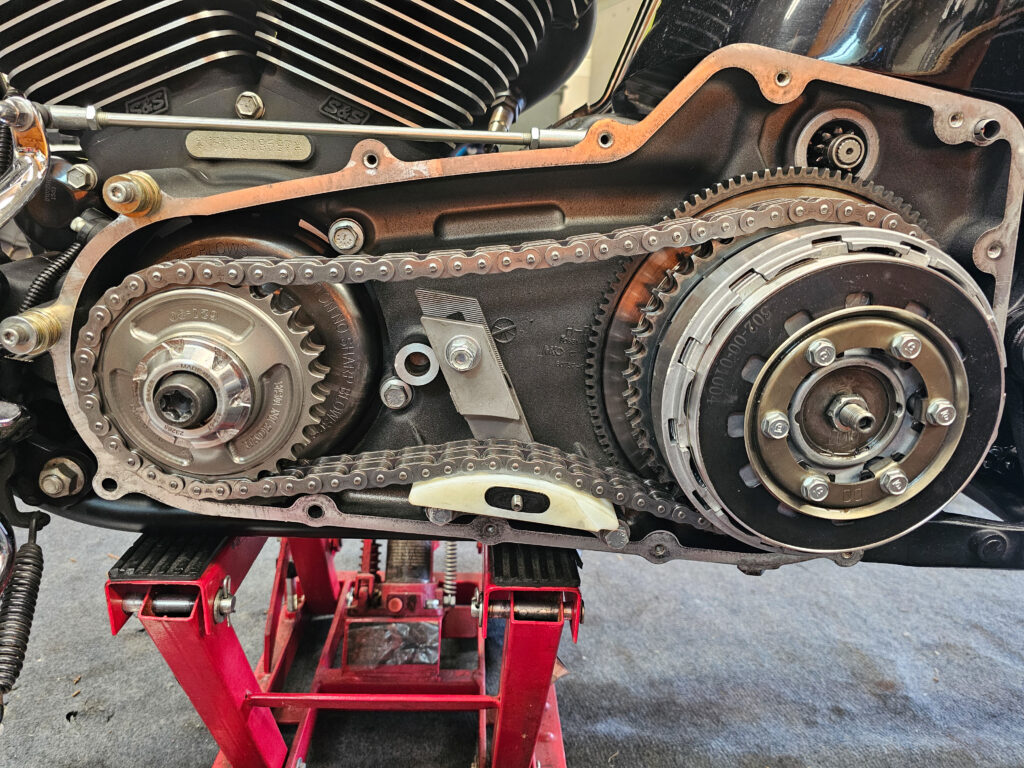

Armed with the info I needed, I ordered a kit with black sprocket, and black/chrome 530 sealed chain with a

sprocket ratio that closely matched the factory belt drive. When it arrived, I was impressed to see the quality of

the CNC pieces they had supplied. Everything about it, seemed, well, “beefy.”

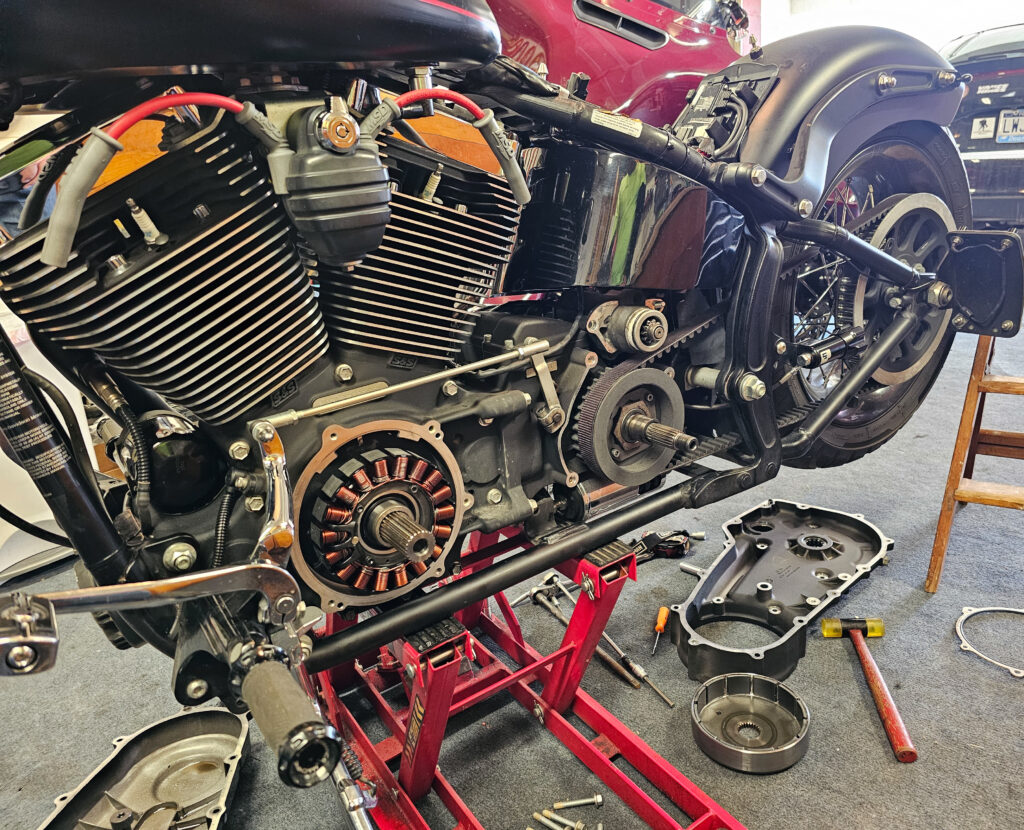

And so began the tear down, completely removing the inner and outer primary, compensator, clutch, and final

drive. This of course took a lot longer than I had anticipated because I forgot to check for special tools I’d need to

get everything apart. Once I sourced the tools, things went a bit smoother. The install went very well. Everything

just fit. No messing around, fumbling, banging, or fenagling. I was getting excited looking at it, absolutely loving the

look, even if the primary wasn’t back on.

Since the primary was completely apart, it didn’t make much sense to put all the old parts back in, especially since

the compensator was questionable. So, I looked to Baker Drivetrain to see what they offered. Not knowing exactly

what I was looking for or what I needed I gave them a call for some guidance. I could have just swapped out the

compensator and been back together then I was asked, “Are you happy with how it drives and accelerates? What

kind of riding do you do? After a good conversation, I was told they’d just released an updated 30-tooth

compensator kit that would give the bike more oomph off the line and also raise the RPM in any gear a little bit.

Fuel mileage be damned, I was sold. Not only did it include the compensator, it also came with a shorter primary

chain and I added the Attitude Adjuster chain tensioner. In for a penny, in for a pound.

The parts arrived, and I was like a kid at Christmas. I couldn’t wait to get it together and see how it rode. This was a

surprise performance boost I wasn’t expecting that could change the attitude of the bike even more than I had

already. Yet again, parts from a made-in-the-USA machine shop just have a different feel to them. Much to my

surprise, Baker isn’t the giant manufacturing facility. It too is a small family run operation making parts for bikers,

by bikers. The bluest kind of collar and the same spirit that drives this build. https://bakerdrivetrain.com/

The actual install went very smoothly with nothing really of note. Everything was made to perfect tolerances and

required no manipulation to fit it together. An important thing the directions mentioned was that I would need to

re-adjust the primary chain tension after a few hundred miles, as the chain stretches. Not a problem, and

completely expected with a manual-type adjuster.

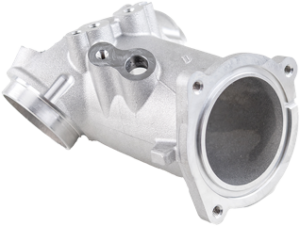

Once again, for the final assembly, I went with Cometic Gaskets. One phone call and I got a kit with everything I

needed to seal this back up. I am still amazed at the quality of their gaskets and seals, and the completeness of

their kits. I have used nothing but their gaskets for this entire project and have had no problems, leaks, or missing

parts. You might think gaskets are nothing to be excited about, but seeing something leaking that took hours to

assemble is like a kick to the gut. Cometic gaskets have proven to be 100% reliable. https://www.cometic.com/

With everything back together, I got out for a ride. Wow, what a ride this was! The compensator was a perfect

match to the cams and really made the bike easier to ride, especially around town. These cams like to rev, and the

30-tooth compensator lets them. At full throttle, it runs through the gears (if I keep the tire smoke to a minimum).

1 st through 3 rd go by really quick, the speedometer looks like a tach with how fast it moves. Speed limits are broken

in the blink of an eye and triple digits come up alarmingly quick.

The fun factor has definitely been turned up a notch or two, but there’s more to it than that. The compensator has

made commuting to work or just casually cruising on back roads easier and more enjoyable, especially with bigger

cams that love to rev. Idling through traffic or managing stop-and-go traffic lights is easier. It just pulls away

smoother and has, in every way, made the ride nicer. But it also makes it meaner when you grab a hand full of

throttle and your ass tries to catch up to your hands. As with everything, the seat of the pants equation is amplified

when you increase the power going into it.

As summer has rolled into fall, Alyssa and I have been racking up miles and adventures as much as we can –

between work projects that spill into weekends, boy scout activities with the kids, and the occasional trip to the

hospital. But the feeling I get every time I hit the start button or tap the shifter with my foot and twist the grip, the

long days, hard work and stress melt away. Where will this project go from here? Is there an end? Will there be

another one? Do I need another bike? Those are questions that will only be answered in time… Stay tuned, though,

there’s always something around the next corner.

More Stories

THE FOLDS OF HONOR RE-MANUFACTURED MOTORCYCLE BY JOHNNY MAC’S CHOPPER HOUSE

THE “POPEYE BUILD, BY JOHNNY MAC’S CHOPPER HOUSE IN PHILLY.

BLUE COLLAR BLACKLINE, PART 8