There are a few sounds that can bring a smile to your face with a sense of accomplishment – mixed with a shadow of crushing doubt. That first pop from the exhaust had me experiencing all of that, along with utter disbelief. Late on a Saturday night, I pressed the start button and nearly shat myself when the bike suddenly came to life. I was so unprepared for it, I didn’t even try to record the first attempt (Who really wants to record the press of a button that inadvertently set fire to the house because of a forgotten O-ring or haphazardly placed pan of flammable substance that would be disposed of “tomorrow”?).

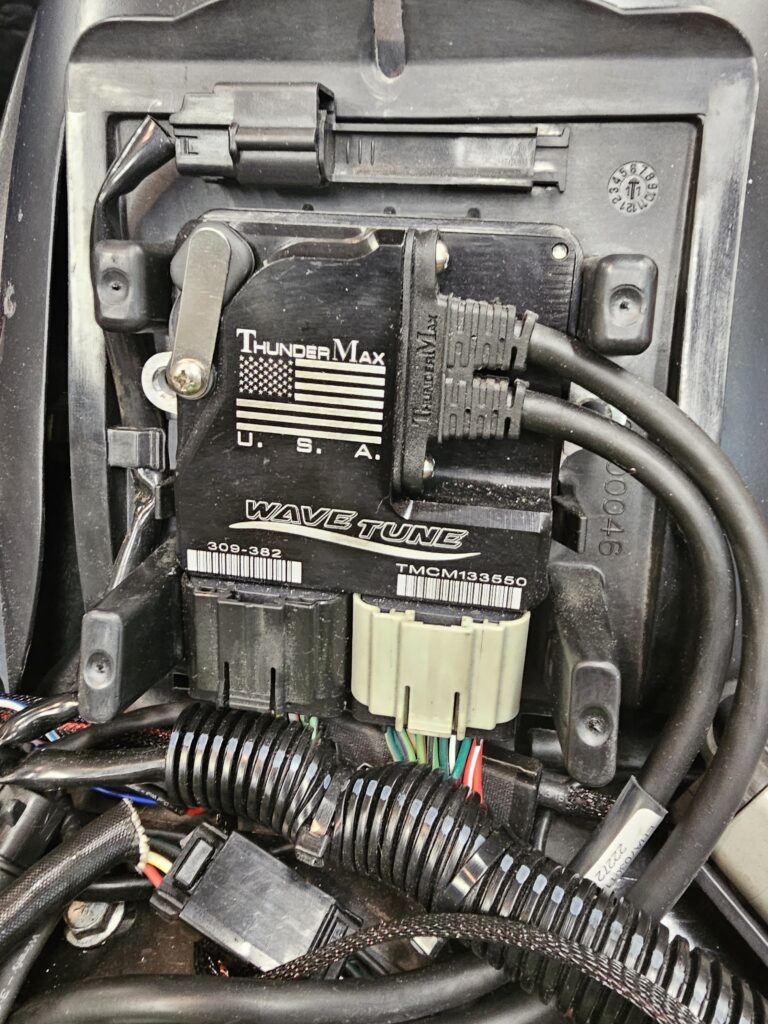

With the bike finally back together, it was time to clean up the pile of old parts on the bench, pans of oil and kerosene, and hardware bits – and address the elephant in the room. In planning this build I knew I was gonna need to do some fuel control that was beyond the scope of the previously installed FP3. While I was juggling the engine parts that were being shipped out, shipped in, bought here, and shipped there, I was researching fuel controllers and options. Again leaning back on my resident H-D guru at work, it was recommended I take a hard look at either a ThunderMax tuner or a local dyno guy who’s known in the tri-state area for getting accurate tunes on big displacement builds.

Wanting to stay as close to the “home build” as I could, and generally having an over blown “I can do that” attitude, I went with the ThunderMax. Having the ability to make any changes, be hands on with how the bike is running, and not being tied to a dyno guy when I make a change down the road, was exactly what I wanted. With others praising how well their bikes run with a ThunderMax and reading nothing but good things about them, I figured it fit my project perfectly and had the track record to ensure success.

The install was incredibly easy. Not having the top half of the engine in the way, battery removed, and full access to everything made it so simple it took only a few minutes. But even with an assembled engine, it could easily be installed with no disassembly needed. Following the directions for routing the wiring harness for the O2 sensors was easy. Thunder Max includes a very detailed, full color instruction book to make sure you get the routing just right.

While I was building the engine, and after I had the final numbers on compression, etc., I sent a support request to ThunderMax for base map selection help. They responded quickly and I was ready to go as soon as I put the engine together. I did spend some lunch breaks at work watching videos from some of the well-known ThunderMax installers and did what I could to learn as much as possible about how the tuner worked.

Next thing I know its late on a Saturday night at the end of April. Alyssa is upstairs with a friend watching chick flicks, I’m in the garage, putting the final touches on the bike. I drop the battery in, make the last of the connections, power up the bike… No smoke. All the angry pixies seem to be staying in the wires. Hook up the laptop, follow the prompts on the ThunderMax software, load the map they recommended, turned on the live monitor and hit the button. Holy shit… It fired up immediately; I panicked for some damn reason and shut it off. Laughing at myself, I collected my thoughts and went back over the heat cycle plan for the coated pistons (it’s a bit different than the standard way due to the graphite coating). I set up a camera to record, double checked the live data link in the ThunderMax software, and did it again… But this time I was ready for it.

I’d love to tell you that the next morning, I took it out for a ride, got the auto tune worked out and enjoyed a full day of breaking it in, racking up the break in miles. In actuality, I did the heat cycles that night, then changed the oil and called it a night around midnight. The next day, we hopped on a flight for vacation. While sitting on a lounger on a beach, Alyssa over-heard the video on my phone of the bike idling more than once; I was secretly excited to get home and run this thing…

Finally home, I was up early and pushing the bike out of the garage. The sound at idle is exactly what I was hoping for. There’s something about the intensity of the exhaust (even at idle) with aggressive cams and high compression. Just letting it warm up in the driveway, I couldn’t wipe the smile from my face. That first ride I was hyper sensitive to every bump, noise and rattle. It went without incident and I quickly focused on doing the “Riding Session” that would help the ThunderMax dial in the tune more quickly while staying in the RPM limits for breaking in a new engine. The next 500 miles went smoothly, as I continued to ride the bike with more and more throttle, racking up miles over the next couple weeks. At 500 miles, I changed out the 15w-40 conventional oil, and switched to a synthetic 20w-50 and new filter. Now it was time to enjoy it a bit more.

That first time I rolled on the throttle in first, grabbed second gear and held on; it was shocking how much the bike had changed. The way the power comes on! It hits hard right at 3000 rpm and doesn’t stop pulling. The throttle response is insanely quick and clean, no stumble, no coughing. Twist the grip and power is there. My first hand, first time experience with wide band tuning on such an extreme scale, was largely uneventful, just as Thunder Heart had intended with the ThunderMax. For both the DIY guy like me and even experienced engine builders, having such a user friendly tuner with fantastic support and ability is invaluable.

I had one small issue of a hard start when the temps were below 70°F. I did a data collection and emailed it to ThunderMax support. They got back to me within 24 hours and made the recommended changes (took longer to find the keys to get the seat off than to make the changes,) and they mentioned the cranking speed was bit slow. While making the changes, I noticed I had swapped in the basic lead acid battery when I was dicking around in the garage with lights, etc. So I swapped back to the lithium battery with a lot more cranking amps, and it fired up nearly instantly. Other than that, the bike has been running amazingly well.

Having put a few thousand miles on it now, it has held together, and continues to run way better than I hoped. I don’t know what I was expecting, but it wasn’t this good. A flip of the clutch, a twist of the grip and the ass end gets loose, predictably swaying side to side as a haze of smoke rolls off the tire… I may start buying shares in tire companies and stock up on tooth brushes. I can’t stop grinning when I twist this dragon’s tail.

Yes, my friends still give me crap for riding the “little bike” when Alyssa and I show up somewhere and she’s on her Street Glide. But at least I can retort with, “Yeah, but mine is the fast bike now”.

More Stories

THE FOLDS OF HONOR RE-MANUFACTURED MOTORCYCLE BY JOHNNY MAC’S CHOPPER HOUSE

BLUE COLLAR BLACKLINE, THE END IS NEAR

THE “POPEYE BUILD, BY JOHNNY MAC’S CHOPPER HOUSE IN PHILLY.